Was ist Closed-Loop-Manufacturing?

TALK WITH USClosed-Loop Manufacturing ist ein Konzept, das unter der Aufsicht von Professor Maurice Pillet durch die SYMME Forschungslabor an der Universität Savoie Mont Blanc in Frankreich. Closed-Loop Manufacturing ist eine Weiterentwicklung von SPC (Statistical Process Control) und beinhaltet die Verwendung digitaler Tools zur Steuerung eines Produktionsprozesses, um bessere Qualitätsergebnisse zu erzielen als mit herkömmlicher SPC.

Heute wird Closed-Loop-Manufacturing in vielen Bereichen industriell eingesetzt, und seine Vorteile sind allgemein anerkannt. Bei Maschinenwerkzeugen hat Closed-Loop-Manufacturing die Umrüstzeiten um einen Faktor von drei oder vier reduziert und die Schrottrate um den Faktor zehn verringert. In jüngerer Zeit wurde sie auch auf andere Arten von Prozessen wie Biegen, Spritzgießen, Extrusion usw. angewandt, wobei ebenso eindrucksvolle Ergebnisse erzielt wurden.

Closed-Loop Manufacturing wird durch eine dem Bediener zur Verfügung stehende Software umgesetzt, die die notwendigen Prozessanpassungen auf der Grundlage der Messung eines oder mehrerer Teile berechnet.

Closed-Loop Manufacturing basiert auf zwei grundlegenden Prinzipien:

Steuerung komplexer Prozesse durch die gleichzeitige Korrektur von Dutzenden von Kontrollparametern

Korrektur der Prozessdrift durch eine Dämpfungsfunktion

1. Controlling Complex Processes

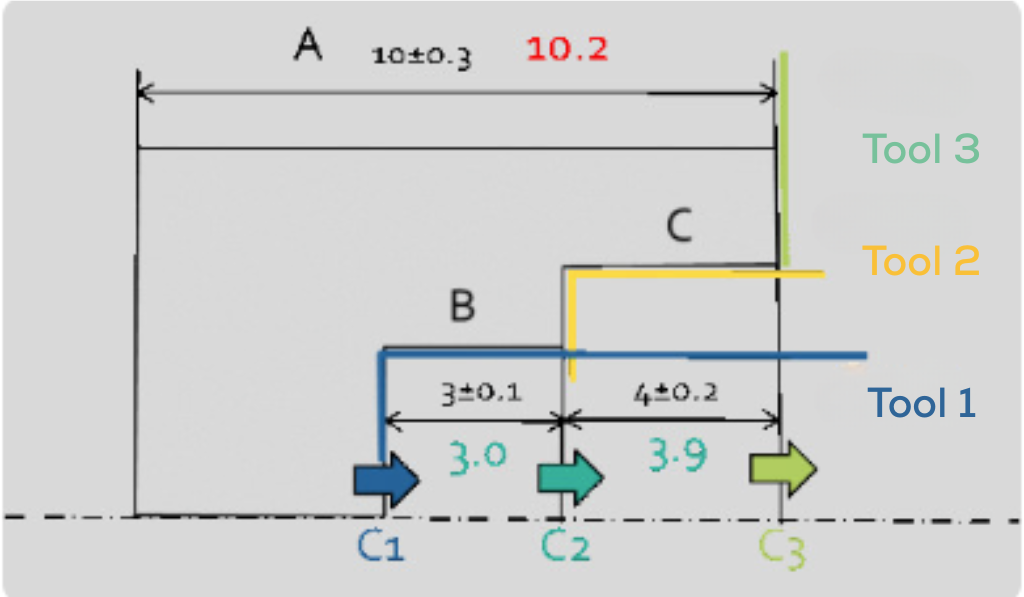

Bei der Überwachung komplexer Prozesse, die mehrere voneinander abhängige Messungen beinhalten, wie z. B. die Bearbeitung komplexer Teile, ist die Maschineneinrichtung oft eine schwierige Aufgabe. Zum Beispiel:

You want to correct measurement A denn bei einem Wert von 10,2 liegt sie außerhalb der Toleranz.

Um dies zu korrigieren, müssen Sie die Position von Werkzeug C3; doing so will also affect dimension C, die derzeit innerhalb der Toleranzgrenze liegt.

Daher müssen Sie auch das Werkzeug anpassen C2-Emissionen, die sich wiederum auf die Messung auswirken werden Bund so weiter.

Der Operator steht dann vor der Herausforderung, zu bestimmen, wie er die Werkzeuge anpassen soll. C1, C2und C3 to bring measurement A zurück in die Spezifikation.

Auch wenn dieses Beispiel einfach erscheinen mag, sind die Teile in Wirklichkeit viel komplexer, und der Anpassungsprozess kann eine erhebliche Menge an Zeit in Anspruch nehmen.

Closed-Loop Manufacturing automatisiert den Anpassungsprozess

Um dieser Schwierigkeit zu begegnen, berechnet eine Closed-Loop-Manufacturing-Software wie CLOOMA automatisch die optimale Einstellung für jedes einzelne Werkzeug.

Die Automatisierung des Anpassungsprozesses basiert auf einer Konfigurationsdatei, die selbst erstellt werden kann:

- a) Von der individuelle Auswirkung des jeweiligen Werkzeugs, oder

- b) Von a 3D-Messdatei des Teils

a) Aus den individuellen Auswirkungen jedes Werkzeugs

In diesem Fall beinhaltet die Konfiguration der CLOOMA Software die Bestimmung, wie sich jeder Steuerungsparameter auf die gemessenen Eigenschaften auswirkt.

Die Frage, die Sie stellen müssen, ist einfach: Wenn ich diesen Parameter ändere, welche Eigenschaften werden davon beeinflusst?

Sobald die individuellen Auswirkungen bestimmt sind - etwas, das während der Produktindustrialisierung nur einmal getan werden muss - berechnen die Algorithmen von Ellistat automatisch die erforderlichen Anpassungen für jedes einzelne Werkzeug.

Das Ergebnis könnte z. B. lauten:

C1: -0.3 C2: -0.3 C3: -0.2

b) Aus der 3D-Messdatei des Teils

In diesem Fall ist die Konfiguration der CLOOMA-Software sogar noch einfacher. Sie importieren einfach eine 3D-Messdatei und geben die Arten von Korrekturparametern an, die von der Maschine verwendet werden. CLOOMAs Algorithmen verarbeiten den Rest und berechnen automatisch die optimalen Einstellungen.

Unabhängig von der gewählten Konfiguration muss der Bediener keine manuellen Berechnungen mehr durchführen-die richtigen Einstellungen werden automatisch bereitgestellt.

Vorteile der Einführung von Closed-Loop-Manufacturing

Im Vergleich zu herkömmlichen Methoden der Prozesskontrolle bietet die Closed-Loop-Manufacturing zahlreiche Vorteile:

Monitors dozens or even hundreds of characteristics simultaneously

Automatisch Beziehungen zwischen mehreren Korrekturparametern ermitteln

Eliminiert Berechnungs- und Vorzeichenfehler

schlägt die wahrscheinlichste und konsistenteste teamübergreifende Anpassungsmethode vor

2. Correcting Process Drift

The limits of SPC (Statistical Process Control)

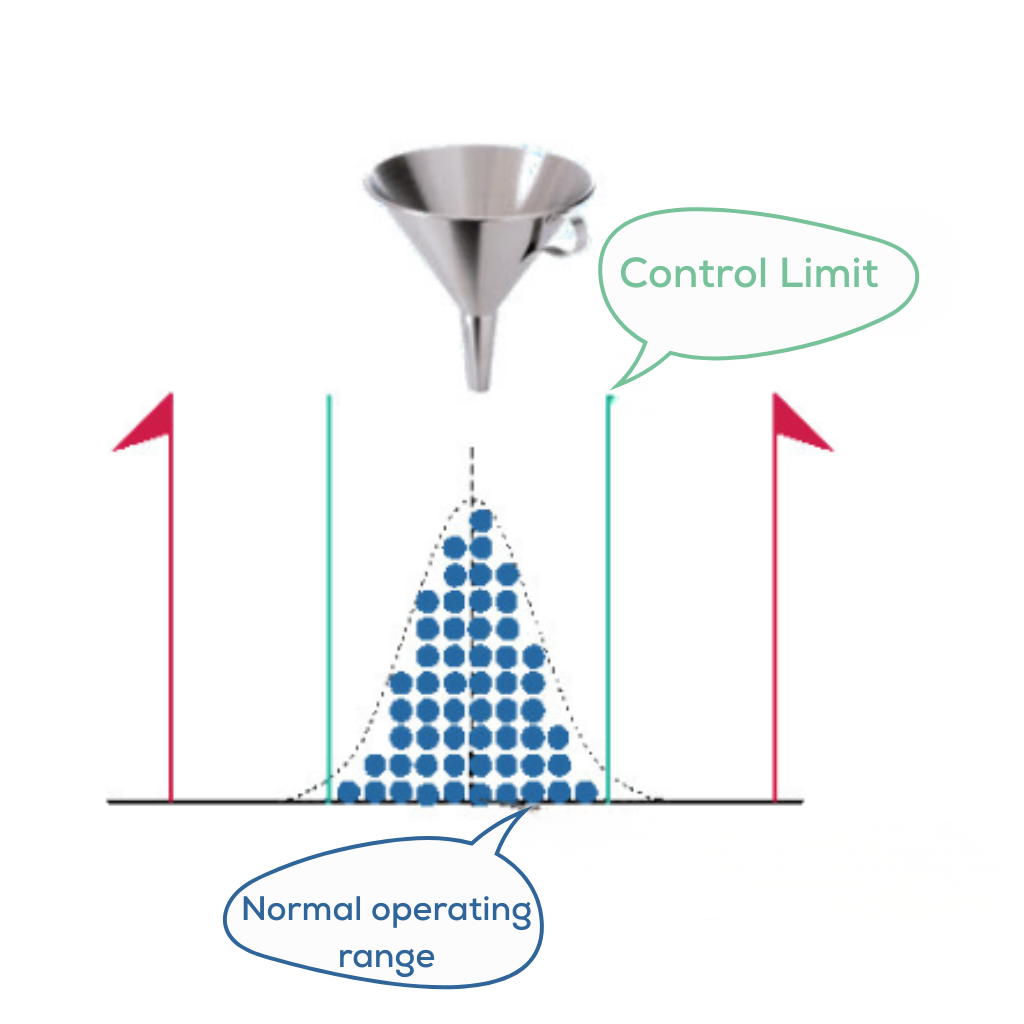

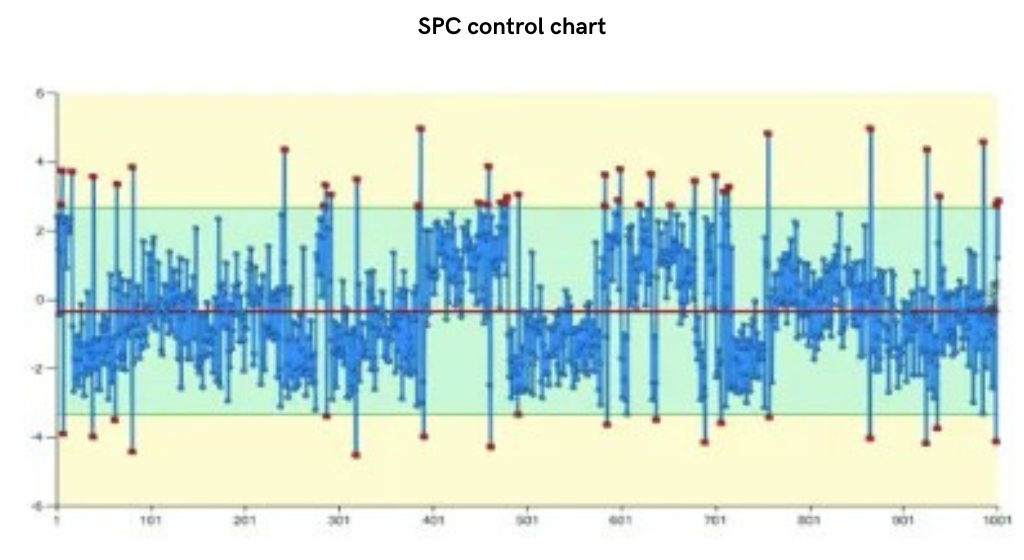

In der SPC-basierten Prozesskontrolle werden Kontrollcharts zur Überwachung der Variation verwendet. Der Prozess wird als stabil angesehen, solange die Messungen innerhalb der Kontrollgrenzen bleiben. Wenn ein Messwert außerhalb dieser Grenzen liegt, zeigt er an, dass der Prozess aus dem Ruder gelaufen ist und angepasst werden muss.

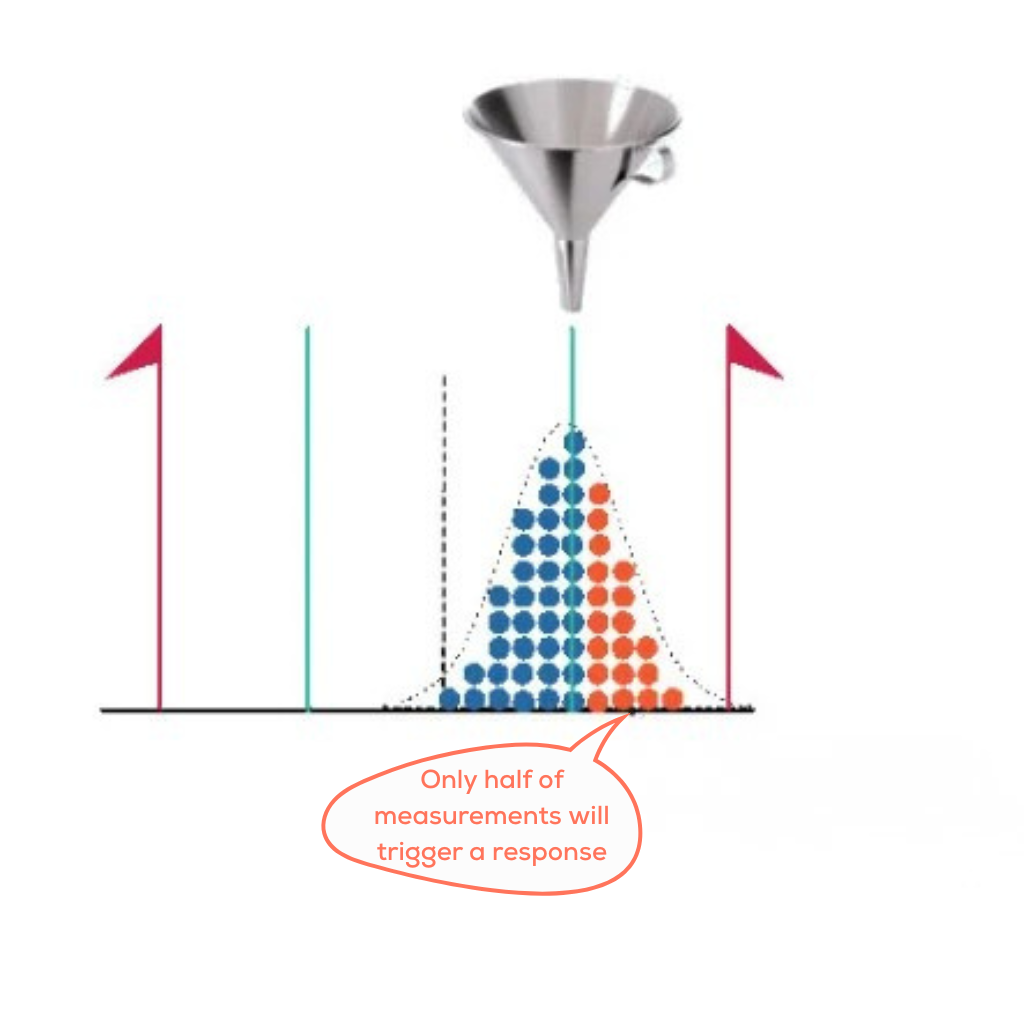

Das Problem mit SPC ist, dass es erst reagiert, wenn der Prozess bereits deutlich abgedriftet ist.

Im folgenden Beispiel hat der Prozess begonnen zu driften, aber nur etwa die Hälfte der Messungen fällt außerhalb der Grenzwerte, was bedeutet, dass die Korrekturmaßnahmen zu spät kommen.

Die Dämpfungsfunktionen des Closed-Loop-Manufacturing

Using digital tools to compute adjustments allows for much more precision than the binary "inside/outside" logic of SPC.

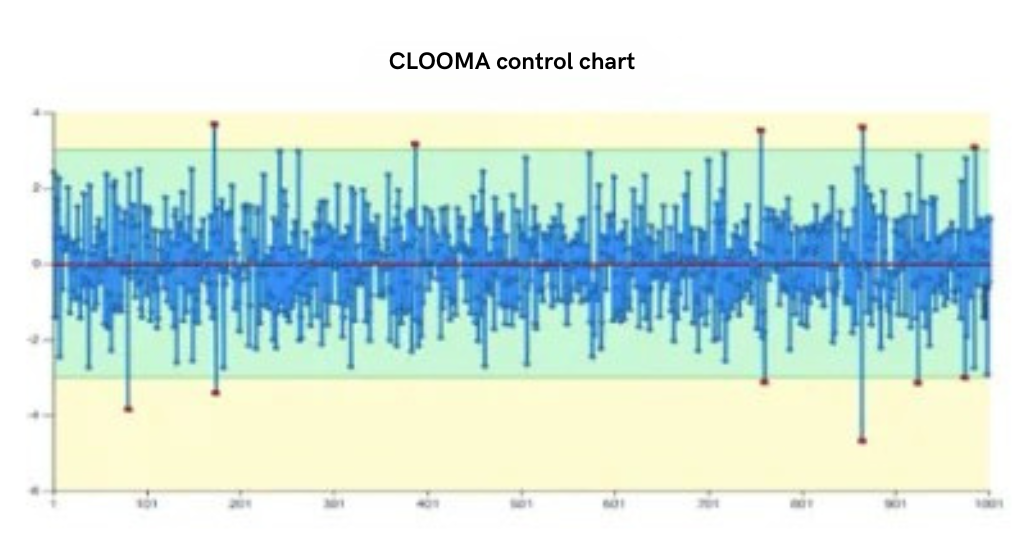

Bei CLOOMA wird der Prozess kontinuierlich - bei jeder Messung - korrigiert, um die Abweichung zu minimieren.

Die Implementierung von Closed-Loop-Manufacturing-Software liefert im Vergleich zu herkömmlichen SPCs weitaus bessere Ergebnisse.

Die folgenden Beispiele veranschaulichen die Prozessüberwachung mit SPC versus CLOOMAs Software:

Mit herkömmlicher SPC überwachter Prozess :

Same process monitored with CLOOMA software :

Schlussfolgerung

Durch Automatisierung der Produktionsprozesssteuerung, Closed-Loop Manufacturing enables quality levels that were previously unattainable and significantly increases machine utilization by minimizing downtime due to adjustments.

CLOOMA-Software ist die erste Softwarelösung, die die Prinzipien der Closed-Loop-Manufacturing vollständig umsetzt. Ihre Implementierung ist einfach und hat transformative Auswirkungen sowohl auf die Produktivität als auch auf die Qualität.

Ob zur Überwachung eines driftenden Prozesses oder zur Steuerung eines komplexen Prozesses, CLOOMAs Algorithmen vereinfachen die Aufgabe des Bedieners und führen eine völlig neue Denkweise in Bezug auf die Prozesssteuerung ein.

The Benefits of Implementing Closed-Loop Manufacturing

Setup-Teile auf eins reduziert: Closed-Loop-Manufacturing minimiert die Anzahl der benötigten Einrichtungsteile. Scrap aufgrund des Setups (typischerweise 1-3%) wird um einen Faktor von drei verringert.

Minimierte Setup-Zeit: Bei der automatischen Justierung wird nur ein Teil benötigt, um eine Maschine zu kalibrieren. Die Einrichtungszeit wird drastisch verkürzt, wodurch sich die Maschinen-Uptime erhöht. So kann beispielsweise ein Getriebegehäuse, für dessen Einrichtung vor der Einführung von CLOOMA ein halber Tag benötigt wurde, nun in nur 30 Minuten (ein Produktionszyklus) angepasst werden.

Maximierte Qualitätsindikatoren: Closed-Loop Manufacturing reduziert die Anzahl der nicht tolerierten Teile im Vergleich zur herkömmlichen Kontrolle dramatisch. Die Erfahrung zeigt, dass Schrott aufgrund nicht konformer Teile deutlich reduziert wird, mit Ppk-Werte übersteigen 1.33 über alle Merkmale hinweg.

Operatorentraining an einem einzigen Tag: CLOOMA zu implementieren ist bemerkenswert einfach - Operatoren können in nur einem Tag voll ausgebildet werden.

Let's talk about your factory