CLOOMA : Close the loop, master the future

Clooma delivers closed loop manufacturing to US factories, an end-to-end platform built in Chicago to automate your machine tools and optimize real-time production.

Discover the Closed Loop

Unlock Closed Loop Manufacturing performance

With CLOOMA's Closed Loop Manufacturing software, you can set up your machine tools in a single part and achieve higher-precision results than with traditional SPC or manual adjustments.

Once CLOOMA calculates the correctors, they are automatically send back to the CNC to complete the closed-loop and ensure consitent quality.

Closed Loop Manufacturing

is now a reality with CLOOMA

Your savings

-90%

LESS SCRAP

-75%

SHORTER SET-UP TIMEs, fewer machine stoppages

$ 20K

SAVED

$20k / machine / YEAR

$20k / machine / YEAR

Why Clooma ?

Automation you can trust

Clooma closes the loop between machines and data, bringing closed loop manufacturing you can rely on every shift.

Continuous improvment

With real-time data feedback, Clooma doesn't just monitor, it learns, adapts and drives your process toward zero-defect manufacturing. Every cycle makes the system smarter.

Sustainable performance, measurable ROI

Reduce scrap, lower energy use and empower your team with automation that pays for itself. Clooma delivers measurable ROI while supporting a sustainable industrial future.

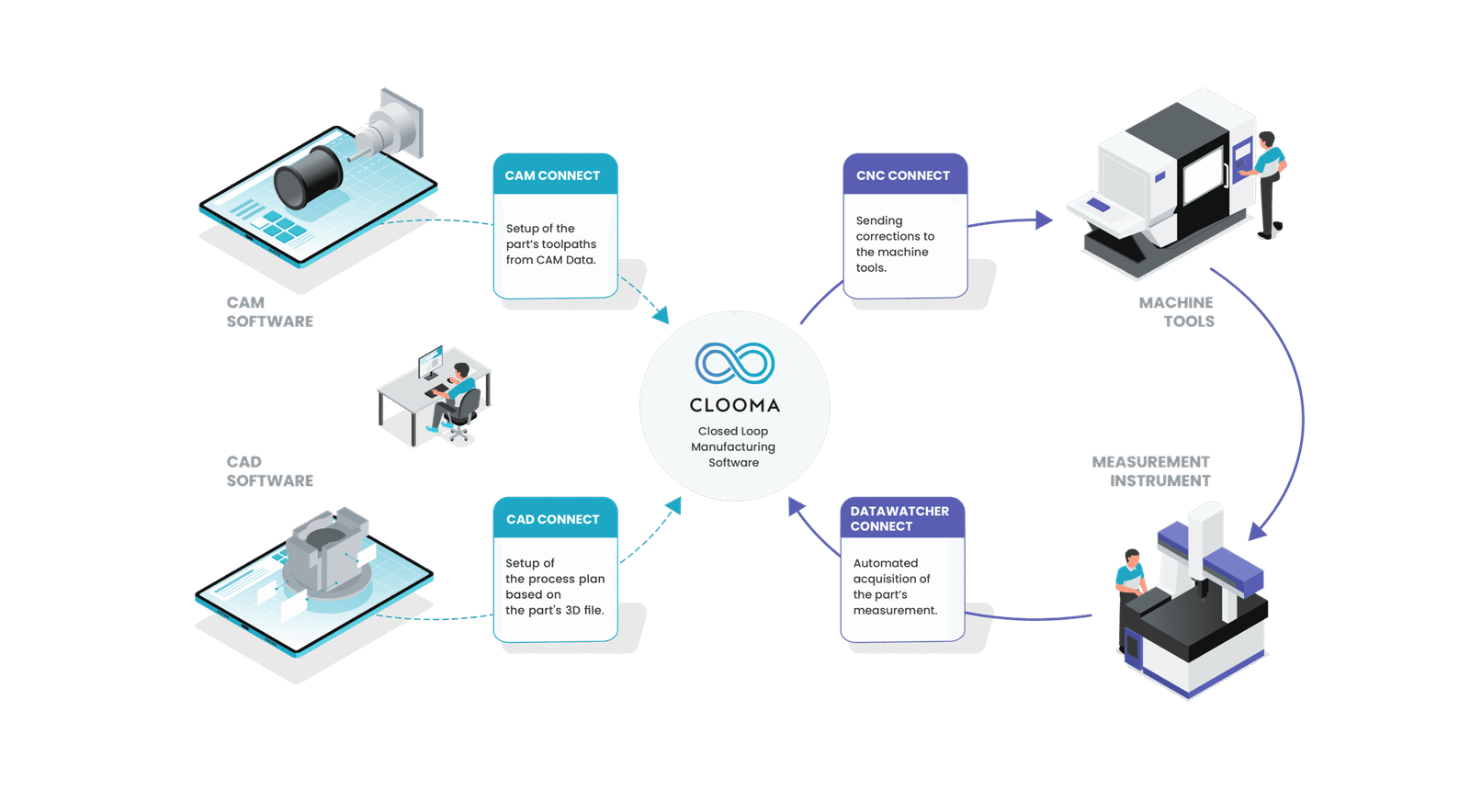

How does it work?

Backed with two PhDs and 15 years of research, CLOOMA uses advanced machine-learning algorithms to deliver the closed loop manufacturing.

Whether the part is simple or highly complex (turning, milling or multi-process), Clooma automatically adjusts each CNC machine tool in real time.

As the system corrects process drift, it learns from its own adjustments. Every cycle makes the model smarter, more stable and more precise.

Clooma is at the core of Industry 4.0, combining automated machine setup with continuoys quality improvement to bring performance to your shopfloor.

Whether the part is simple or highly complex (turning, milling or multi-process), Clooma automatically adjusts each CNC machine tool in real time.

As the system corrects process drift, it learns from its own adjustments. Every cycle makes the model smarter, more stable and more precise.

Clooma is at the core of Industry 4.0, combining automated machine setup with continuoys quality improvement to bring performance to your shopfloor.

Key Features

Connection to CNC machines

- Send calculated corrections directly to the CNC machine program, automatically and in real time. CLOOMA integrates seamlessly with major machine-tools brands such as : Fanuc – Siemens – Mitsubishi – Mazak – Heidenhain – Okuma – Tornos – Beckhoff...

Automatic calculation of correctors

- CLOOMA automates the entire setup process. The operator produces a part on a machine, measures it, and the algorithm instantly calculates the corrections to be applied to the machine to correct the process.

- Each correction ins applied with maximum accuracy to limit drift, while the system continuously learns from its own adjustments to improve over time.

Configuration from CAD and CAM files

- Closed Loop Manufacturing setup is fully streamlined. Dimensional information is extracted directly from CAD files while machining parameters are imported from CAM programs.

- Because the configuration is fast and automated, closed loop manufacturing becomes accessible for both high-volume production and short runs.

Real-time SPC

- Real-time generation and updating of control cards (X-bar, R, P, NP, etc...)

- Instant creation and display of histograms

- Real-time drifts and anomalies detection

- Alerts and notifications in the event of non-compliance

- Automated control reports with customizable templates

Capability calculation and monitoring

- Calcuation of Cp, Cpk, Pp, Ppk indices

- Trend monitoring of capability indices over time

- Detailed analysis of process capability against specifications

Standards compliance

- Fully aligned with ISO 9001, AS/EN ISO 9100, and ISO 13485

- Compliant with FDA CFR 21 part 11 requirements

Integration with existing systems

- Available On-Premise or Cloud, full web-based architecture

- API for integration with MES, ERP and other production management systems

- Import and export data via CSV files and other formats.

Intuitive user interface

- Customizable dashboards

- Clear, intuitive view of control data

- Accessible from any device (PC, tablets, smartphones)